Heres the .410 hand load set I built.

In the back is the de-capping tool, then the priming rod/wad seater. In front of that is the shell chamber. To the right is my miniature version of a spin doctor hull conditioning tool. Behind that is my roll crimper, both of these tools are used in a drill.

First put hull in shell chamber and use de-capping tool to drive spent primer out (no, it doesn't require a hammer).

Seat a new primer with the priming tool.

Add charge, seat wad and add shot.

Close with the roll crimper in drill press.

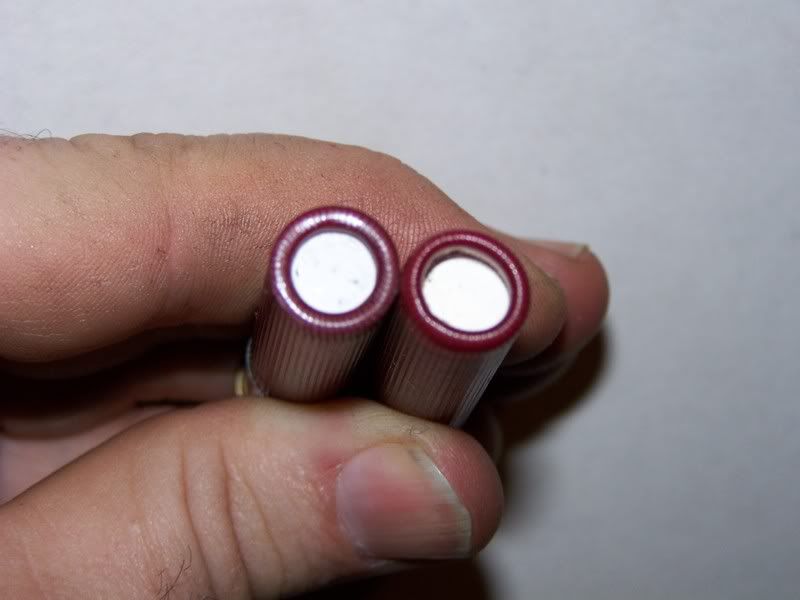

My crimp on the left, factory crimp on the right.

Whole process takes less than a minute.

--------------------

Shawn Wheaton

Missouri Waterfowl Association

Westside Chapter Chairman

|